Fluid bed Dryer

Fluid Bed Dryer is equipment is very versatile process equipment for efficient drying of products, and is used to remove moisture content from wet fine solids by transforming liquid into vapor by products fluidization. It works on the principle of creating a fluid turbulence in a granulated wet product by means of hoi air flowing in an upward direction and dries the same to the required degree in a careful manner.

Capacity Available :

5Kg. to 500kg.

FBD can be supplied in electric heating or steam heating.

The drying time depends up on various factors such as physical properties of material, moisture content etc.

Selection of capacity of FBD depends upon bulk density, drying temperature and moisture content of wet material to be dried.

Salient Features :

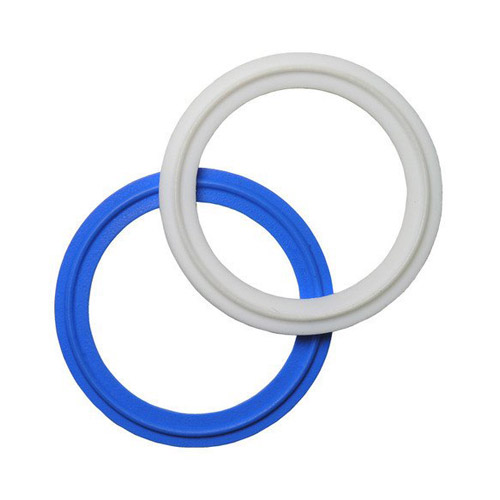

Inflatable silicon rubber tube is using for sealing the Filter bag.

Low voltage relay with positive earthling arrangement.

Online sampling device.

Fully automatic operation with PLC control.

For lifting and sealing of product container pneumatically operated gasket is attached.

Auto pneumatic shaking with timers & Actuator valve.

Differential pressure gauges to monitor pressure across inlet filter and filter bags.

Electrical locking between inflatable gasket and the motor with alarm.

Silicon rubber gasket between product container & retarding chamber.

Solid flow monitor at exhaust.

Optional Features :

Flame proof system

PLC Control Panel

Steam heated or Electric heated Blower.

AHU with HEPA filters